-

Posts

468 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Forums

Hunting New York - NY Hunting, Deer, Bow Hunting, Fishing, Trapping, Predator News and Forums

Media Demo

Links

Calendar

Store

Everything posted by dinorocks

-

It also depends on the side of the tree you tap...many of my south facing taps are (were) running and the north facing taps weren’t (they will run later)...the sun warms the south side of the trees before the north side warms up. I boiled yesterday and despite the afternoon below zero temps, I had drips coming from some of my south facing taps (while the sun was out).

-

This is a very helpful shooting video my friends made yesterday behind the house...the instructor (Mark) is one of the best traditional archers I know and was/is one of my shooting mentors.

-

Looking good mowin!

-

My wife and I got most of our trees tapped this afternoon...sap was flowing (dripping) on the sunny sides of the trees. Great day to be in the woods!

-

Congrats! Perfect weight to work on form with. I see many people buy 55# plus to learn on and hunt with...in my opinion, if the bow is too heavy, it is harder to practice over long periods of time and form degrades fast. I recommend meeting up with experienced instinctive shooters to work on form before you potentially develop poor shooting techniques that are hard to break. Also, check out Fred Asbell’s instinctive shooting videos...he even talks about shooting a compound bow instinctively. Pick up some blunts...perfect weight for stump shooting! have fun!

-

My wife and I hauled the last of our syruping stuff out to the sugar shack. All the trees are marked and ready to tap! Got my “ice castle” built this afternoon at one of my sap storage outposts...those 8 inch thick ice blocks were challenging to lift out of water but I’m ready for the sap! Not long now!

-

Looking good Mowin! That’s going to be a big sugar shack! I read somewhere...if you plan a sugar shack, make it twice as big as you think you need. Keep us posted on the progress! I’m tapping on Sunday as I see day time temps are getting close to 40! Picked up some supplies and another 165 gallons of storage. I have some new things I’m going to try this season to make my small operation more efficient! Took some time off this week to cut ice blocks from the creek...I’m planning to make an “ice house” for one of my outpost storage areas.

-

Wow, nice! Much bigger operation than what I have going behind the house! I’m bringing back my buckets on sleds today...storage containers went out a couple weeks ago and I have already chopped enough ice blocks from the creek to keep future sap cold for the entire season. Based on the current weather forecast, it’s looking like at least a couple more weeks before I tap, and into March before I start boiling (western NY). I typically get three boils per season...about 250 gallons of sap per boil. Lots of work hauling buckets of sap by hand and cleaning equipment between boils...not to mention splitting wood to “arm diameter” pieces! It takes me 1 hour to evaporate 10 gallons of sap...a true labor of love!! And if I were to buy syrup, I would not complain about spending $50 for a gallon of syrup!! keep us posted on your sugaring! Happy evaporating! Dino (a couple years ago my buddy asked if he could interview me on my backyard maple syrup “operation”... https://m.youtube.com/watch?v=BEqNmyL-sno

-

I recommend that you look into becoming a member of http://www.wcgmc.org They have a lapidary shop for members and the members are a wealth of knowledge!

-

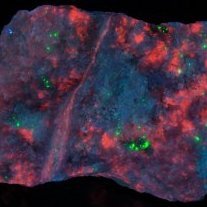

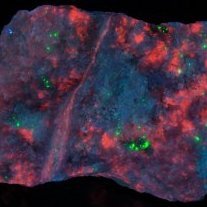

Glad they arrived! The arrow is pointing to polished agate...there are many types of agate...think those are fire agate. I was a bit rushed when I put the package together and may have missed some other labels ...some of my favorites I sent included the bag of petrified wood (polished) and the dinosaur poop (unpolished)...that one should be easy to wire. If the Buffalo Geological Society has its show this year at the Erie County fairgrounds (typically mid-late March), they sometimes have wiring classes...and there will be lots of supplies available. Enjoy and please send me some Picts of your work down the road. (and let me know if you have any other ID questions).

-

I was tempted to use a mixer but the one I was looking at had a plastic drum that I could not heat. I’ll probably use my method (or close to it) again next time as things worked out pretty good for me. Regarding cooling, I dumped my hot wax dirt back into my jet sled and used a metal rake to mix it. I found it cooled quicker when the sled was on my cool concrete floored garage. Unfortunately I will not be making much wax dirt next year because my K9 trapping plans this year didn’t pan out. (I have about 50 gallons currently stored).

-

I didn’t cover it so the moisture could escape. After it was dry from sitting on a dark tarp on my black driveway in the heat of the summer, I transferred it to a couple black Jet sleds and added my wax. With the Jet sleds I could easily mix it and pull it in the garage when needed. I found that the sunlight alone wasn’t completely melting the wax so I transferred it in 3-gallon batches to a large canning pot and heated it over a propane grill...once I got the hang of it, the process went fairly quick and it was very obvious when it was done because it noticeably darkened. It was also obvious when it was heated too much (smell and smoke). A couple take-aways I learned; 1. Sand alone works great...organic material is very bad as it sucks up too much wax. 2. make sure the dirt is 100% dry before adding wax. 3. Test the waxed dirt often so you know if you need more wax. You cannot add too much wax. If you spend all the time and effort and money making wax dirt and not enough wax was added, when it gets wet, it WILL freeze when the temps drop. I.e., it will not work, period, for its intended purpose. 4. Note number 3 above needs to be repeated if your dirt source/conditions change. 5. Once off the heat, Keep mixing wax dirt until it cools...if not, you will end up with a solid block and will need to reheat/re-cool. I’m by no means an expert but learned lots through trial and error and discussing with those more experienced...feel free to reach out to me with questions...if I cannot help, I have lots of mentors I can solicit for answers. good luck!

-

Ha! Isn’t your pond on a farm too? Let me know when you and Kaiden want to join me!

-

Another bow...the small one was from a few days ago...the fatty was yesterday.

-

Left Field you are correct....our ice is not pebbled although for fun, we will try (bought several gallons of deionized water for our sprayer). For official tournament ice, the rounded tops of the pebbling would need to be shaved off...our “zamboni” is not that precise. We watched a video (how-to prepare ice for competition) and that, unfortunately is way over our pay grade! For example, after pebbling (with a known amount of DI water) they would shave the tops of the pebbles, collect the ice shavings , melt in a microwave and weigh to determine if they need to cut pebbles down or re-apply... https://m.youtube.com/watch?v=50cSDUIDMuM

-

Lots of hockey! Two metal nets and reinforced thick PT plywood boards for quick-rebound puck passes...the boards are taller on the ends to keep puck in play longer. I think I mentioned earlier, we typically put LED lights under the ice for the lines (not this year though)...we plan to continue to use the router/colored crepe paper for the rest of the season. The only bad part of the crepe paper is the darker colored areas of the ice melt quicker when the sun is out.

-

@mlammerhirt #mlammerhirt (not sure if I should use "#" or "@") Our first Zamboni was made for a pond by our house....we insulated a 65 gallon tank and filled with hot water. The tank was on a trailer towed by an ATV...the tank gravity-fed the water down a short vertical piece of PVC to a 6-foot horizontal 1 1/2" PVC pipe with holes that were small diameter near the effluent end of the vertical PVC and increased in diameter (to control even water distribution). The ends were capped and we connected dense carpeting behind the horizontal pipe...this helped to spread the water and knock down any high spots (frozen slush) on the ice. Between passes (as needed) or before applying water, we fitted a 6-ft long 6x6" timber with a metal plow blade that was dragged behind the ATV...the blade helped smooth the ice (cut down high spots). We also cut a hole in the ice and installed a pump that we used to fill our tank (battery operated). Hot water helped "heal" the ice when it was in rough shape and the cold water was used for routine maintenance. Now with our rink behind our house, we can micro manage the ice and seldom need to use the steel blade. And with hot/cold water only a couple hundred feet away, we have large lengths of hose that we use instead of the tank. The application is similar except we hand pull the PVC...we have a towel on the back end instead of carpet because the ice is generally very smooth. It is very helpful to have a second person manning the hose so it doesn't drag across areas recently wetted/freezing. We also only use a thin layer of water and repeat as necessary. Lastly, drain the hose when finished and store horizontal...if the hose is coiled and hanging vertically (even when "empty), residual water will drain to the low section, freeze, and block the hose. Hope the above helps!

-

Yes, a very bright light! I’ll be here all evening...send me a PM if you are in the area.

-

You need to join us next time! Heck, come on out today and slide some stones with me (send me a text if you can make it Jay).

-

As a follow up to my earlier post on making curling stones, yesterday we held our First Annual Bonspiel! There were 10 teams that entered and we played double-elimination bracket style. Curling started at 12:30PM and continued into the wee hours of the night! We had a fire going, kept well hydrated, and I grilled up an assortment of venison sausages from Costanzas along with some elk chili I made. One of my neighbors who played with us owns a brewery and we enjoyed several growlers. Another person brought a guitar but it was a bit too chilly to pick some strings. Being outside, we could practice proper social distancing. Great times had by all and planning another Bonspiel next weekend if the weather cooperates! Below are a few picts of us setting up the house (rings), prepping the ice and sliding some stones.

- 24 replies

-

- 24

-

-

If needed, I have a large collection of “beach glass”. I spent the last 20+ years working in Massena (USEPA) and rented a camp on an island on the St.Lawrence River. My kids and I would comb the shoreline and found glass sporadically. To increase our supply I picked up lots of colored glass from garage sales, broke it up and and put in two “beach glass makers” we constructed. The first was made from a basketball ball we found washed up on the shore. I cut a “lid” in the ball, added glass, sand and a little water then sealed it up. I then anchored the ball in the river (the ball was floating on the surface of the water). I deployed the beach glass ball in the river for two years (pull it out before ice up and back out after ice out in the spring). The wave action would cause the ball to bop around and the sand slurry would smooth the glass. The second setup was a large cage I made with wire mesh. I filled the cage with assorted glass and staked it in the water along the shore line in a sandy area...the waves would move the sand back and forth over the glass and smoothed the glass. I kept this one out for three years. Both methods worked great albeit a bit slow. Again, let me know if I can send you some.

-

Happy to help! Just let me know!

-

Wanted - 9/32" field points (>125 gr)

dinorocks replied to dinorocks's topic in Hunting Items For Sale and Trade

Thanks! PM sent. -

Wanted - 9/32" field points (>125 gr)

dinorocks replied to dinorocks's topic in Hunting Items For Sale and Trade

Thanks Larry...unfortunately I don’t think they are going to fit properly. Well now that I think about it, maybe if the threading fits, it would be ok if the point is wider than the shaft (just need to test the point weight). I may have some 5/16 (100 gr). I’ll try and get back to you. Take care!